March 15, 2024 (Middletown, Conn.) — Connecticut State Community College Middlesex unveiled new plastics machinery equipment and upgrades to their manufacturing training facility located at Vinal Technical High School in Middletown. State and local legislators and representatives from area manufacturing firms joined Connecticut State Colleges and Universities (CSCU), CT State and Middlesex officials to celebrate the completion of the lab during a ribbon-cutting ceremony on March 15.

“Connecticut has one of the strongest and most skilled manufacturing workforces in the country. CT State Middlesex’s new state-of-the-art manufacturing lab at Vinal Technical High School will provide our students with a world-class education that will provide them with the hands-on training needed to pursue a lucrative career in advanced manufacturing. Through these efforts, Connecticut will continue to lead the way in the manufacturing sector and ensure our workers ‘Make It Here,’” said CSCU Chancellor Terrence Cheng.

“Connecticut has one of the strongest and most skilled manufacturing workforces in the country. CT State Middlesex’s new state-of-the-art manufacturing lab at Vinal Technical High School will provide our students with a world-class education that will provide them with the hands-on training needed to pursue a lucrative career in advanced manufacturing. Through these efforts, Connecticut will continue to lead the way in the manufacturing sector and ensure our workers ‘Make It Here,’” said CSCU Chancellor Terrence Cheng.

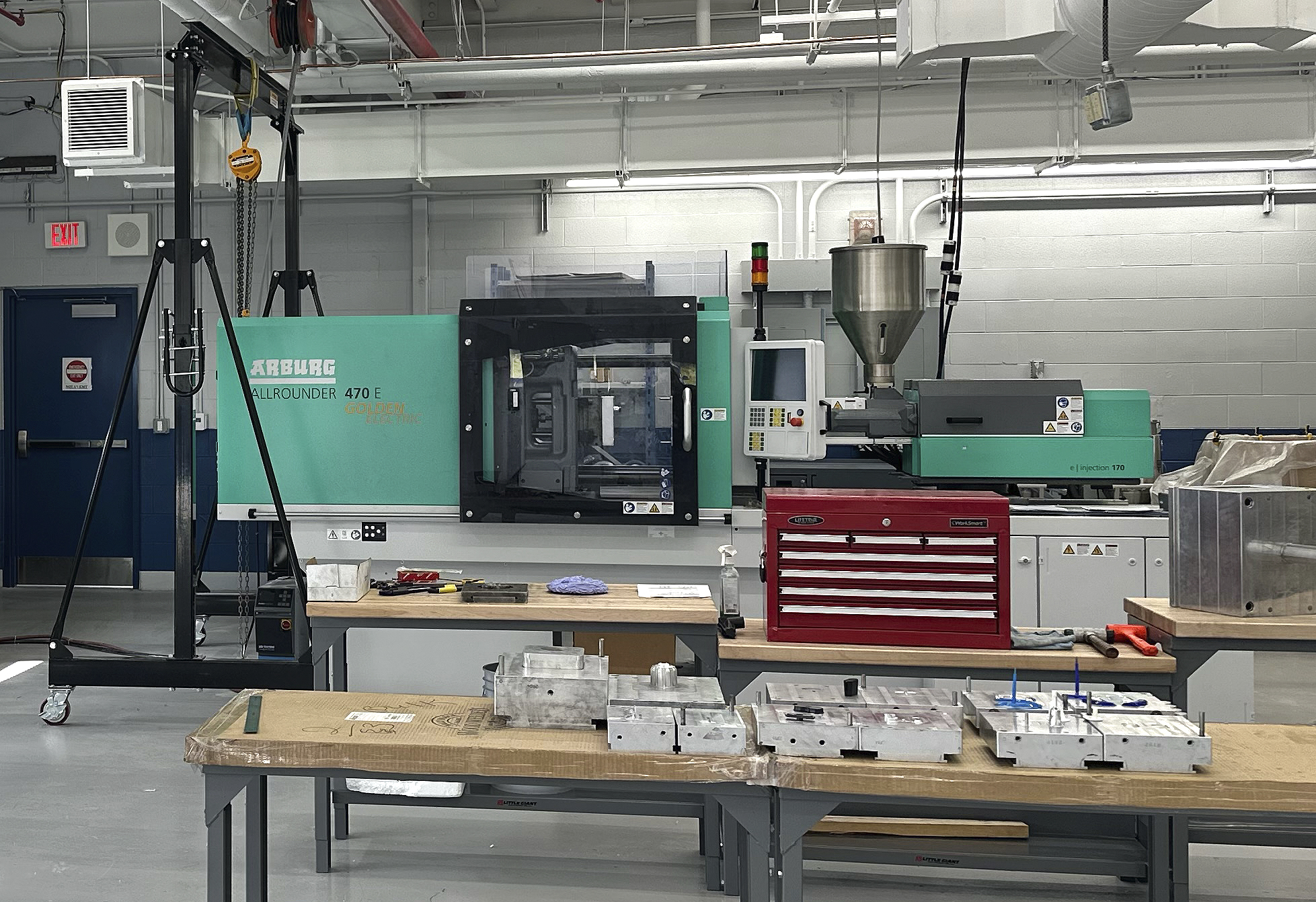

The facility features a new plastic injection molding machine provided by Arburg, Inc., known as the Allrounder 470 E Golden Electric. According to the Arburg website, the company is one of the world’s leading manufacturers of plastic processing machines.

“The Arburg machine is very adaptable to different situations within the process. Students can interact with the controller which gives them visual access and helps them understand what is going on during each step of the process,” said Roland Kim, Regional Manager at Arburg. “As an industry, we don’t have enough trained people to operate these machines.”

In the lab, students are taught the basics of plastic injection molding, covering machine setup, operation and processing. Plastic injection molding is integral to the production of everyday consumer goods, such as medical parts and devices, packaging, protective equipment, toys, car parts, and more. Students use retired molds of medical equipment parts to acquire practical experience with the procedure.

The educational setup includes Smart teaching technology in two classrooms, which provides learning software for interactive lessons and online resources. Students also have access to a metrology lab to practice using measurement tools.

“The collaboration between Middlesex and Vinal exemplifies how partnerships can make a difference. Arburg’s donation demonstrates how our industry partners were invested and engaged in the solution to meet the workforce needs in our state. We are proving that the dollars supporting public education—offering training and education to the workforce of our state—yields the highest return on investment,” said Kimberly Hogan, Chief Executive Officer, CT State Middlesex. “It took years to get us to today’s opening event—a very proud day for CT State Middlesex.”

“The collaboration between Middlesex and Vinal exemplifies how partnerships can make a difference. Arburg’s donation demonstrates how our industry partners were invested and engaged in the solution to meet the workforce needs in our state. We are proving that the dollars supporting public education—offering training and education to the workforce of our state—yields the highest return on investment,” said Kimberly Hogan, Chief Executive Officer, CT State Middlesex. “It took years to get us to today’s opening event—a very proud day for CT State Middlesex.”

CT State offers an advanced manufacturing machine technology associate degree program as well as a certificate. The college is currently reviewing a new curriculum for plastic injection molding, which is set to begin in the fall.

Middlesex has been hosting the Skill Up for Manufacturing Workforce program at the site since 2019. This free, five-week initiative allows graduates to gain the skills needed to move quickly into entry-level manufacturing jobs.

The current cohort is comprised of individuals from the Uniquely Abled Academy, an exclusive program for neurodiverse young adults. Alex and Zachary are two students who will graduate this month. “As part of a work exercise, we recently produced 35 Lego planes with no defects, the first time in the lab,” they said.

The college has operated the manufacturing facility in partnership with Vinal Tech for several years and also offers classes at Wilcox Technical High School in Meriden.

“The transformation of this space is simply amazing,” said Vinal Tech Principal Nelson Rivera. “This center is a win for both of our schools, for Middletown, for Middlesex county and all of Connecticut.”

Additional lab equipment includes an industrial chiller from Frigel and a compressed air dryer from DRI-AIR Industries, as well as molds from Wepco Plastics, Inc. The lab is also equipped with three TRAK TRL 1630RX lathes, two ProtoTRAK KMX K3 knee mills and a TRAK K3 mill.

Prospective students may check the college’s website to enroll in the degree or certificate programs or to apply for the next Skill Up class.

With the merger of the 12 Connecticut community colleges on July 1, 2023, CT State Community College is now the largest community college in New England, enrolling more than 70,000 students each year, and approximately 25 percent of college students in Connecticut. As the most affordable college in the state, CT State is dedicated to making quality education accessible to all in a supportive and inclusive learning environment. CT State students benefit from a streamlined financial aid process and apply once to take classes at any campus. The campuses—Asnuntuck (Enfield), Capital (Hartford), Gateway (New Haven and North Haven), Housatonic (Bridgeport), Manchester, Middlesex (Middletown and Meriden), Naugatuck Valley (Waterbury and Danbury), Northwestern (Winsted), Norwalk, Quinebaug Valley (Danielson and Willimantic), Three Rivers (Norwich), and Tunxis (Farmington and Bristol)—form a network that empowers students to tailor their educational journey to their needs.